① According to the specific conditions of the equipment, such as the length of the heating area, the material of the heating source, the structure of the reflow soldering furnace and the heat conduction mode, etc.

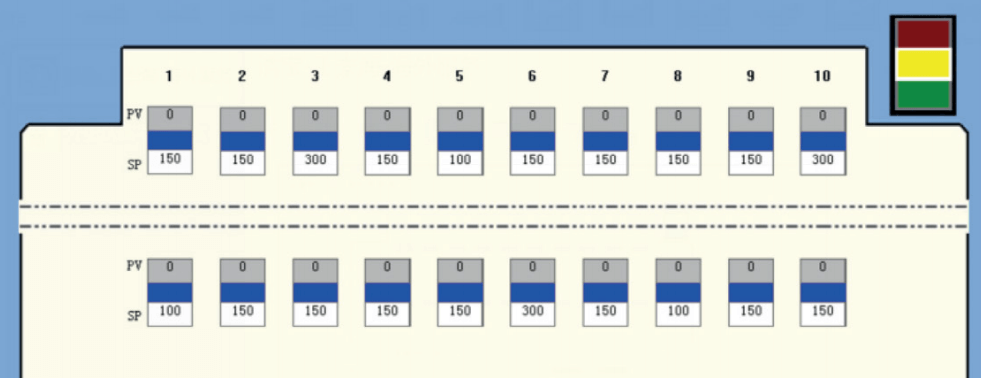

Reflow oven temperature setting

②Set in keep with the temperature curve of the solder paste used. Solder paste with different metal content has different temperature curve. The reflow temperature curve of specific product shall be set according to the temperature curve provided by solder paste supplier.

③Set according to the size of exhaust air volume. General reflow soldering furnace has specific requirements for exhaust air volume, but the actual exhaust air volume sometimes changes due to various reasons.

When determining the temperature curve of a product, the exhaust air volume shall be considered and measured regularly.

④The setting temperature of each temperature zone is determined according to the actual position of the temperature sensor. If the temperature sensor is located inside the heating body, the setting temperature is about 30 ℃ higher than the actual temperature.

⑤ Set according to the material, thickness, multi-layer board and size of PCB.

⑥It is set according to the density and size of components on the surface assembly board as well as special components such as BGA and CSP.

With the increase of assembly density of electronic products and the decrease of component size and pin spacing, the difficulty of SMA welding process is increased, the setting range of reflow welding temperature curve parameters is narrowed, and welding quality problems are easy to occur. The correct design of welding process, especially the accurate setting of welding temperature curve, has become one of the key contents to ensure the quality of SMA assembly.

Keywords:

SMT Product Line, LED Assembly Line Machine, Screen Printing Machine For SMT, Printer Stencil PCB, 6 Reflow Oven, Air Filter For Reflow Oven, Soldering Bath Machine, PICk And Place Machine PCB, PICk And Place Machine TVm926, PICk And Place Máquina Usada, PneumatIC PICk And Place Assembly, THT PICk And Place Machine, Yamaha PICk And Place Machine, SMT PCB Turn Conveyor, SMT PCB Customized Conveyor, PCB Conveyor With Work Station, Magazine PCB Loader, 5 Axis Solder Iron Robot, 6Bb Pv Module Solder Robot, Rotating Axis Desktop Soldering Robot, AutomatIC Four-Axis Soldering Robot

I.C.T is a manufacturer of SMT machines. It mainly provides customers with SMT production lines including SMT Stencil Printers, Pick and place machines, Reflow Oven, AOI Machine, Wave Soldering Machine and PCB Handling Machine etc. I.C.T has more than 25 researches on SMT and DIP technology, for the world Customers provide SMT total solutions. There are successful cases of SMT technical team in Asia, Europe, America, Africa, and Australia.

I.C.T provide SMT solutions at various stages according to the different needs of customers. I.C.T is not only a provider of SMT equipment and technology, but also is the customer's escort in the field of SMT and DIP.

Welcome more people to discuss with us about SMT technologies and solutions, please contact us for more information:

Tel: +86 13670124230 (WhatsApp/Skype/WeChat)

Email: etasmt@foxmail.com