This convection reflow oven is ideal for low-volume lead-free printed circuit board soldering production lines.

- 6 upper and 6 bottom forced hot air convection zones allow high quality lead-free soldering with uniform heating and exceptional process stability

- Temperature accuracy of ±1°C and a high-speed CE certificated blower for maximum convection

- Individual temperature control for all zones

OVERVIEW

Touchscreen controlled lead-free oven with 6 up and 6 bottom full hot air convection zone. Ideal for inline production.

- 6 upper and 6 bottom forced hot air convection zones allow high quality lead-free soldering with uniform heating and exceptional process stability

- Temperature accuracy of ±1°C and a high-speed CE certificated blower for maximum convection

- Individual temperature control for all zones

MAIN FEATURES

- Streamline shape design make the oven looks great. It is panel control for standard machine. Meanwhile we provide touch screen and plc controlling system. It can save 50 groups temperature parameters and provide extra 2 ports for profile testing

- Brand electrical component like Schneider (German) breaker, Omron (Japan) box relay. Meanwhile the CE certificated blower is specially design for lead-free reflow oven. It runs stable and lower noise

- Upper zone, hood and electrical box cover can be opened easily. It is convenient for cleaning and maintenance

- The inner tunnel of the oven is made of stainless steel which can stand the high temperature and easy for cleans

- The entire upper and bottom zones are forced hot air convection

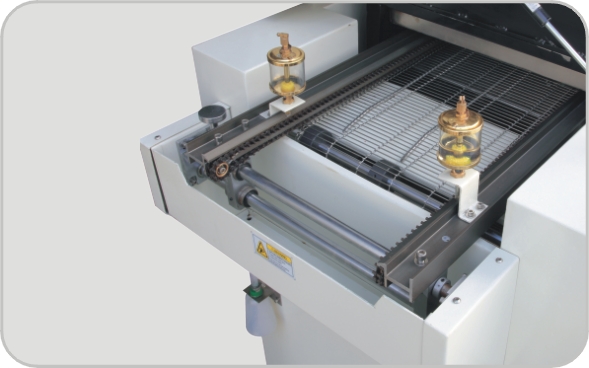

- Stainless steel mesh belt. and chain conveyor and SMEMA

CONVEYOR

Chain and mesh belt conveyor can accept boards up to 300m (11") and handle speeds up to 900 mm/min (35"/min). All rail has been harden-treated and comes with lubrication cup

HEATING ZONES

With 6 upper and 6 bottom forced hot air heating zones get full profile control. Ideal for prototyping, short-run or low production

TOUCHSCREEN INTERFACE

The touchscreen interface allows you to save more than 50 groups of parameters including temperatures, speed and alarm. It also comes with 2 extra thermocouple ports for profiling

CE CERTIFICATED

Built with brand electrical components like Schneider (German) breaker, Omron (Japan) box relay and a powerful CE certificated blower, this oven is specially designed for lead-free reflow processes. Performing very stable runs and keeping noise lower than any other of its type.

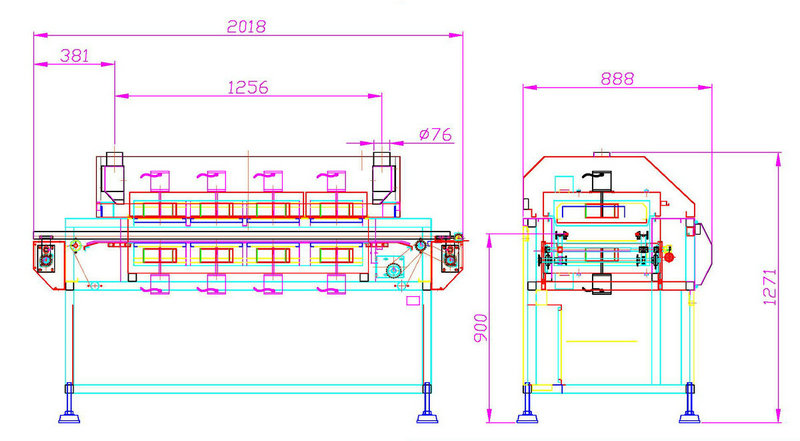

SPECS

| Heating Zones |

Upper 6 hot air zones Bottom 6 hot air zones |

| Heating Zone Length | 60.63in |

| Dimension (no stand) | L2550xW750xH670 |

| Dimension (with stand) | L2550xW750xH1250 |

| Net Weight | 850 Lb |

| General Power | 33KW |

| Consumption Power | Aprox. 7KW |

| Ramp Time | 18 minutes |

| Control Type | Micro-processor control |

| Heat Type | Upper/botton zones fully forced hot air convection |

| Temp control | PID close-loop. SSR drive |

| Temp Range | Ambinent-350°C |

| Temp Accuracy | ±1°C |

| Temp Uniform | ±2°C |

| Cooling Type | 1 cooling zone with CE certificated blower |

| Conveyor Type | Stainless steel mesh belt and Pin Chain conveyor |

| Conveyor Height | 10.63±0.79in(without stand) 35.43±0.79in(with stand) |

| Belt Width | 12.99in |

| Max. PCB | 11.81in |

| PCB Clearance | 1.18in |

| Conveyor Speed | 0-35.43in/min |

| Conveyor Direction | left to right |

| Hood Lift | Manual with help of plenum cylinder |

| Power Supply | 380v,3ph,50hz (Option: 220v, 3ph,60Hz or 220v,1ph,60hz) |

| Package | Vacuuming |

Keywords:

LED Bulb Assembly Line Semi AutomatIC Machine, LED-Line Assembly-Machine, PCB Solder Paste Printer Semi, Semi AutomatIC Solder Paste Printer, LED Reflow Oven, Thermal Profiler Reflow Oven, Wave Soldering Machine Desktop DIP, Conformal Coating Spray Machine SMT, SMT Roll Wiper Rewinding Machine, SMT Peripherals PCB LED Dispensing Machine, SMT PCBA Pour Machine à Laver, Feeder Rack For SMT Asm Machine, Screening Conveyor SMT, AutomatIC PCB Loader, PCB Screening Conveyor, Screening Conveyor PCB, Conveyor Driver Board, PCB Circuit Boards Separator, Heating PCB Separator For Mobile Ipad

I.C.T is a manufacturer of SMT machines. It mainly provides customers with SMT production lines including SMT Stencil Printers, Pick and place machines, Reflow Oven, AOI Machine, Wave Soldering Machine and PCB Handling Machine etc. I.C.T has more than 25 researches on SMT and DIP technology, for the world Customers provide SMT total solutions. There are successful cases of SMT technical team in Asia, Europe, America, Africa, and Australia.

I.C.T provide SMT solutions at various stages according to the different needs of customers. I.C.T is not only a provider of SMT equipment and technology, but also is the customer's escort in the field of SMT and DIP.

Welcome more people to discuss with us about SMT technologies and solutions, please contact us for more information:

Tel: +86 13670124230 (WhatsApp/Skype/WeChat)

Email: etasmt@foxmail.com