Important: Before reflowing starts, turn the oven on to heat up, a minimum of five minutes. Set the oven to bake and set the temperature to the highest baking temperature setting (450 to 500 degrees F).

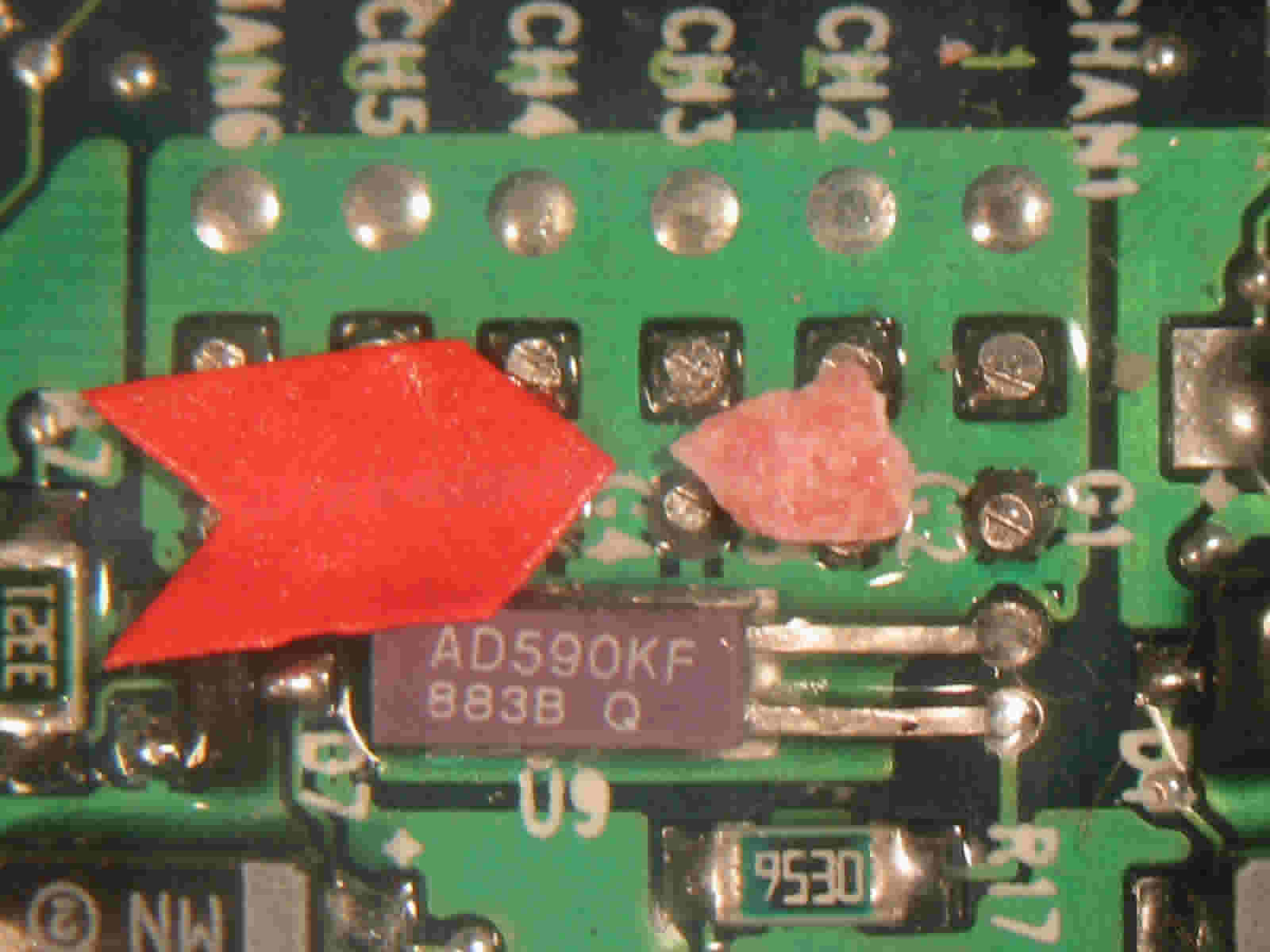

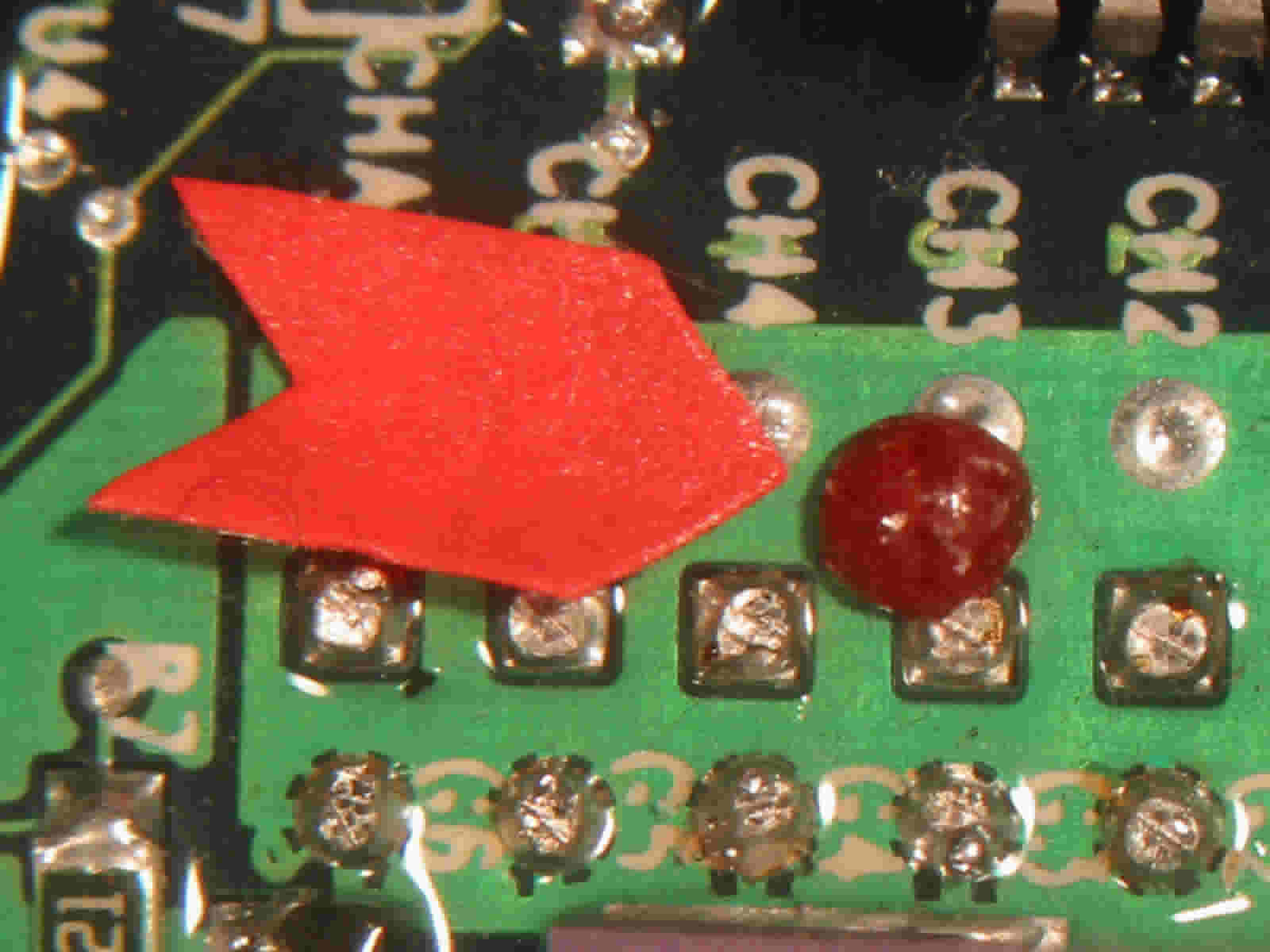

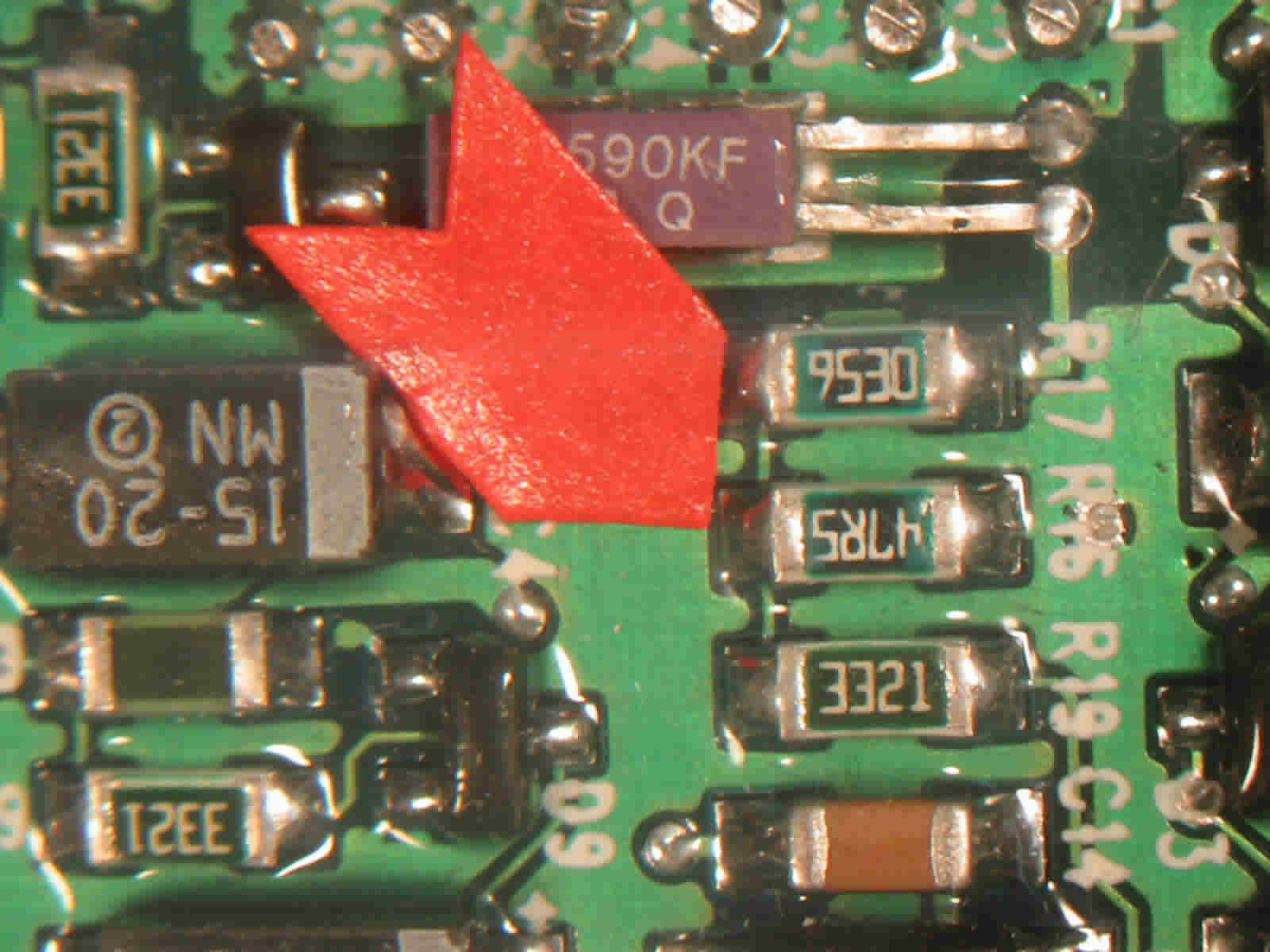

Before placing the PCB in the oven, mark it on the top side next to the edge that will be nearest to the oven door, with the reflow temperature indicator (413 degrees F).

Make sure that you can see the temperature stick mark through the oven door. If the edge of the board has a breakaway do not mark the breakaway, mark the edge of the PCB. If there is not a clear area on the edge of the PCB, mark the interior of the PCB next to a large component (PLCC or QFP) with the reflow temperature indicator.

NOTE: The edges and corners of the PCB will be hotter than the interior of the PCB. If the temperature marker is used on the interior of the PCB, the corners and edges may get too hot and damage the board or the SMT components.

When the temperature indication mark melts, remove the board from the oven. Be careful not to disturb the molten solder joints. Place the board on a surface and let it cool to near room temperature. Inspect the solder joints. Use your solder joint inspection criteria or the IPC 610 requirements.

If you have more than one board, place the next PCB in the oven after marking the board with the temperature stick. If any of the solder joints on the first board did not reflow properly, mark the PCB next to the location that did not reflow with the temperature indicator (413 degrees F). Use this location to control the reflow length for the subsequent boards or to redo the reflow process on the original board.

A flashlight can help when watching the temperature indicator material change in form. When using a toaster oven, this visual method is the only reliable reflow guide. You have to watch the material to judge reflow time. Every board is different so time is not a good control (1 minute, 5 minutes, 20 minutes, etc.). There just isn't any "average reflow time" for these types of projects. To suggest any would only confuse the issue and could actually hurt, rather than help, your project. Remove the PCB after the temperature stick mark melts, let cool and inspect the solder joints. Repeat the above step until all your PCBs are reflowed. Turn Oven off.

Cautions and Handy Information

Warning: Using Common Sense

- Solder paste contains lead. Do not eat or drink around solder paste

- Do not use a toaster oven to prepare foods after it has been used for solder paste reflow.

- Wash hands after working with solder.

- Oven is hot, use insulated gloves and safety glasses while working around hot equipment.

- Some SMT components have restricted thermal process requirements. Verify that all components can be processed using a standard SMT process as described in this procedure.

- Do not store cold pack solder paste in a refrigerator used for food and never store room temperature solder jars in a refrigerator.

- Solder Paste Shopping Guide.

- If you have questions about paste, you want to talk to a reliable source; usually someone other than a distributor. Solder paste manufactures will always answer your questions and you can easily find them on the World Wide Web (search on "solder paste"). You can sometimes purchase small quantities directly from some manufacturers. A better bet might be smaller distributors or you can purchase solder paste as an option in many prototype stencil kits. Here are a few well known paste manufacturers in alphabetical, not priority order, and definitely not the only sources around. This is just a sample for your information:

- AIM

- Amtech

- Cobar

- EFD

- ESP

- Heraeus, Inc.

- Indium Corporation of America

- Kester Solder

- Multicore

- OMG

- Qualitek International, Inc.

- Senju

Learn How to Recognize A Good Solder Joint

I'm sure that many of you are either associated with or at least aware of the Institute for Interconnecting and Packaging Electronic Circuits (IPC). This is the best source I can point you to regarding all the guidelines you need to build and inspect a product worthy board assembly. The documents below are extremely helpful, even if you're an old pro. You can order them, and much more, directly from IPC at the address below.

- IPC 610 is an industry SMT solder joint quality standard

- IPC/EIA J-STD-001C:Requirements for Soldered Electrical and Electronic Assemblies

- IPC-D-279 Design Guidelines for Reliable Surface Mount Technology Printed Board Assemblies IPC

Keywords:

AutomatIC Vacuum Glue Filling Production SMT Line, PICk And Place Machine For PCB Assembly, SMT Machine Manufacturers, Surface Mount Technology Machine, Best PICk And Place Machine, Best SMD Machine, Low Cost SMT PICk And Place Machine, PCB Cutting Machine PCB Lead Cutter, PCB V-Cut Cutting Machine 502, V-Cut PCB Depaneling Machine, Ucuz PCB CNC Router, Depanel PCB, LED PCB Depaneling, V-Cut PCB Separator Machine, PCB Rolling Cutting Machine PCB, Atc PCB Cutting Making Machine

I.C.T is a manufacturer of SMT machines. It mainly provides customers with SMT production lines including SMT Stencil Printers, Pick and place machines, Reflow Oven, AOI Machine, Wave Soldering Machine and PCB Handling Machine etc. I.C.T has more than 25 researches on SMT and DIP technology, for the world Customers provide SMT total solutions. There are successful cases of SMT technical team in Asia, Europe, America, Africa, and Australia.

I.C.T provide SMT solutions at various stages according to the different needs of customers. I.C.T is not only a provider of SMT equipment and technology, but also is the customer's escort in the field of SMT and DIP.

Welcome more people to discuss with us about SMT technologies and solutions, please contact us for more information:

Tel: +86 13670124230 (WhatsApp/Skype/WeChat)

Email: etasmt@foxmail.com