Lead Free Reflow Oven – 8 Zone

From: Author:Lead Free Reflow Oven Publish time:2021-09-14 12:04 Clicks:0

Lead Free Reflow Oven – 8 Zone

Basic Description

The 8 zone reflow oven is the most cost-effective model with long heating length and high conveying speed, owning medium to high production volume. High-precision control mode, maintain a stable and accurate temperature control system.

Adjustable temperature control ability and the blower speed of control separately, it can meet the high precision soldering requirements. Using the windows XP operating system, English and Chinese interface is available.

And it has a step forced cooling system, which can easily achieve the requirements of strict lead-free processes. The track are made of special alum with high rigidity accuracy and intensity.

Feature

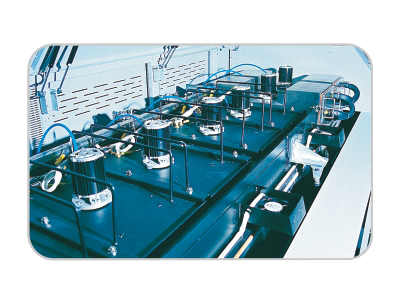

1. Hot Air Motor And Special Heat Wire

- Long axis high temperature motor has the characteristics of automatic cooling, long lasting performance and low noise.

- Specially-made heating wire takes the advantage of star heating body with special coiling. It has the characteristics of quick heating, long lasting performance and low heat inertia.

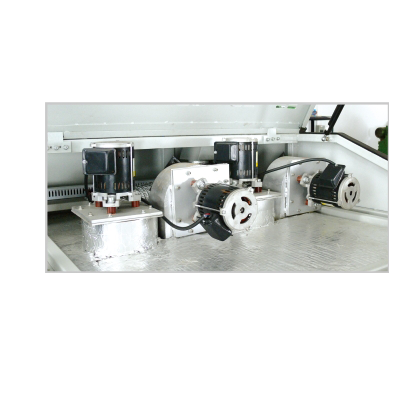

2. Cooling System

- Strong inner-circle refrigeration system, reliable and stable.

3. Guide Rail Width Adjustment

- In-phase gear width-adjusting system, ensure guide rail parallel.

4. New Design Independent Circulation

- Lead-free soldering new designed independent wind blower and hot-air reflow circulation.

5. PC+PLC Control System

- The digital control adopted with PC+PLC control system to maintain stable and repeat position accuracy. Moreover, all major parts are originally imported from the famous brands in the world which has guaranteed the machine is durable and reliable.

Specification

| Models | RO-8840 | RO-8830 | RO-8820 |

|---|---|---|---|

| Heating Zone System | |||

| Number of Heating Zone | Top8/Bottom8 | Top8/Bottom8 | Top8/Bottom8 |

| Length of Heating Zone | 3160mm | 2800mm | 2800mm |

| Number of Cooling Zone | Top2/Bottom2 | Top1/Bottom1 | Top1/Bottom1 |

| Exhaust Volume | 10M3/minX2 | 10M3/minX2 | 10M3/minX2 |

| Warming Time | Approx. 20min | Approx. 20min | Approx. 20min |

| Conveying System | |||

| Maximum Width of PCB | 50-500mm | 50-450mm | 50-600/700/800mm |

| Rail Width Range | 50-400mm | 50-370mm | 50-500/600/700mm |

| PCB Component Height | Top30/Bottom25mm | Top30/Bottom25mm | Top30/Bottom25mm |

| PCB Transmission Agent | Chain+Mesh | Chain+Mesh | Mesh |

| Conveying Speed | 0-1800mm/min | 0-1800mm/min | 0-1800mm/min |

| Conveying Height | 900+/-20mm | 900+/-20mm | 900+/-20mm |

| Conveying Direction | L to R/R to L | L to R/R to L | L to R/R to L |

| Conveyor Rail Fixed | Front rail fixed(option: rear rial fixed) | Front rail fixed(option: rear rial fixed) | Front rail fixed(option: rear rial fixed) |

| Control System | |||

| Temp-Control Mode | PID Full-closed loop control + SSR Driver | PID Full-closed loop control + SSR Driver | PID Full-closed loop control + SSR Driver |

| Temp-Control Range | Indoor Temp-320 Celsius degree | Indoor Temp-320 Celsius degree | Indoor Temp-320 Celsius degree |

| Temp-Control Accuracy | +/-1 Celsius degree | +/-1 Celsius degree | +/-1 Celsius degree |

| PCB Temp-Deviation | +/-2 Celsius degree | +/-2 Celsius degree | +/-2 Celsius degree |

| Cooling Mode | Forced wind cooling | Forced wind cooling | Forced wind cooling |

| Power System | |||

| Initial Power | 36KW | 32KW | 48KW |

| Run Power | 7KW | 6.5KW | 8KW |

| Power Requirement | 3Phase 380V 50/60HZ | 3Phase 380V 50/60HZ | 3Phase 380V 50/60HZ |

| Abnormal Alarm | Extra-high temp or extra-low temp alarm | Extra-high temp or extra-low temp alarm | Extra-high temp or extra-low temp alarm |

| Signal Tower | Three light | Three light | Three light |

Keywords:

SMT LED Assembly Production Line, Complete Line Manufacturer Of SMT Machens, Stencil Product Printer, Combo Stencil Printer Ink, SMT Soldering Machine Lead, EconomIC Reflow Oven, Wave Soldering Machine Mini, Samsung SMT PICk And Place Machine Sm 481, PICk And Place - SMT PICk And Place Machine, SMT LED Lens Feeder For LED PICk And Place Machine, Lens Feeder And PICk And Place Machine, PICk And Place Cajas, PICk And Place Pachine, Nreoden PICk And Place, PICk And Place Labeller, PICk And Place Sucker, PCB Unloader Loader , Stacker Handle PCB, Juki SMT Loader, PCB Conveyor PrICe, Conveyor PCB

I.C.T is a manufacturer of SMT machines. It mainly provides customers with SMT production lines including SMT Stencil Printers, Pick and place machines, Reflow Oven, AOI Machine, Wave Soldering Machine and PCB Handling Machine etc. I.C.T has more than 25 researches on SMT and DIP technology, for the world Customers provide SMT total solutions. There are successful cases of SMT technical team in Asia, Europe, America, Africa, and Australia.

I.C.T provide SMT solutions at various stages according to the different needs of customers. I.C.T is not only a provider of SMT equipment and technology, but also is the customer's escort in the field of SMT and DIP.

Welcome more people to discuss with us about SMT technologies and solutions, please contact us for more information:

Tel: +86 13670124230 (WhatsApp/Skype/WeChat)

Email: etasmt@foxmail.com