IR Reflow Oven

From: Author:IR Reflow Oven Publish time:2021-09-14 12:09 Clicks:0

Basic Description

The IR reflow oven is suitable for infrared radiation curing of the surface coating of the PCB board. This model of IR3C can just meet the curing requirements in the surface spraying process of the PCB board.

It is not only simple in structure, fast curing speed, high production efficiency, but also can reduce production space and has good curing quality. It has become an advanced IR reflow oven in the world.

Feature

1. Control Panel System

- It uses a convenient and simple control panel, which is easy to operate for this IR reflow oven.

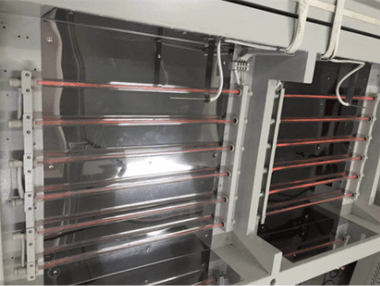

2. Heating System

-

Adopt with the PLC temperature controller and button control, it can achieve precise temperature control in 2 temperature zones.

-

Equipped with 2 temperature zones, it has 6 heating pipes in each temperature zone, to minimize energy consumption.

2. Heating System

-

Adopt with the PLC temperature controller and button control, it can achieve precise temperature control in 2 temperature zones.

-

Equipped with 2 temperature zones, it has 6 heating pipes in each temperature zone, to minimize energy consumption.

3. Transportation System

-

Use of chain conveyor mode, the width of the chains can be adjusted between 50-450mm.

-

In order to meet the customer’s multiple connection ways, the chain uses stainless steel and extended pin chain.

4. Guide Rail Structure

-

It is adopted with the special reinforced aluminum alloy guide rail which can withstand high temperature.

-

Also, the guide rail supports adjustment mechanism to ensure the minimum deformation.

-

The shaking problem of track is avoided, and eliminate the dropping issue if PCB board.

5. Adjustable Transportation Speed

-

Adopt specially reinforced aluminum alloy guide rails, which can withstand high temperature and cooperate with the support adjustment mechanism to ensure the minimum amount of deformation.

-

The track is prohibited from shaking, and the phenomenon of failing off the board is eliminated.

Specification

| Model | IR3C |

|---|---|

| PCB Transfer Height | 920 +/- 20mm |

| Transportation Speed | 0-3500mm/min |

| Transfer Direction | L to R (R to L) |

| Transmission Motor | Stepper motor |

| Delivery Method | Chain conveyor (35B5 extended stainless steel chain) |

| Electric Current | 10A |

| Number of Heating Pipes | 12 units, 6 pipes each zone |

| Number of Temperature Zones | 2 zones |

| Type of Pipes | Infrared quartz heating pipe |

| Adjustable Range of Temperature | Customized temperature-150 degree |

| Heating Time | Less than 10 minutes |

| Max. PCB Board Size | W450mm*L450mm |

| Max. PCB Component Height | +/- 100mm |

| Opening Method | Automatic lifting |

| Power Supply | AC380V 50HZ |

| Total Power | 6.5KW |

Keywords:

Complete Line Manufacturer Of SMT Machines, Complete Line Of LED PCB SMT Machines, Stencil Printer Tattoo Professional, PCB Printer Machine SMT Stencil, Reflow Oven SMT Conveyor, SMT Reflow Oven PrICe, Wave Soldering Machine Input Conveyor, SMT Printing Machine Stainless Steel Setting Needl, Double Sided Terminal Plug In SMT Machine, 4 Heads Multi-Function SMT Labeling Machine, Machine Ramassage Et De Spot Automatique Pour SMT, Double-Sided Terminal Plug In SMT Machine, PCB Substrate Loader, PCB Destacker Magazine Loader, PCB Push Up Destacker Magazine Loader, PCB Stack Unloader, PCB Depaneling Maquin, PCB Depaneling Cutter, Laser Depaneling PCB, Manual PCB Depanelizer

I.C.T is a manufacturer of SMT machines. It mainly provides customers with SMT production lines including SMT Stencil Printers, Pick and place machines, Reflow Oven, AOI Machine, Wave Soldering Machine and PCB Handling Machine etc. I.C.T has more than 25 researches on SMT and DIP technology, for the world Customers provide SMT total solutions. There are successful cases of SMT technical team in Asia, Europe, America, Africa, and Australia.

I.C.T provide SMT solutions at various stages according to the different needs of customers. I.C.T is not only a provider of SMT equipment and technology, but also is the customer's escort in the field of SMT and DIP.

Welcome more people to discuss with us about SMT technologies and solutions, please contact us for more information:

Tel: +86 13670124230 (WhatsApp/Skype/WeChat)

Email: etasmt@foxmail.com