Circuit Board Coating Machine - Feature

From: Author: Coating Machine Publish time:2021-09-15 15:30 Clicks:0

Feature

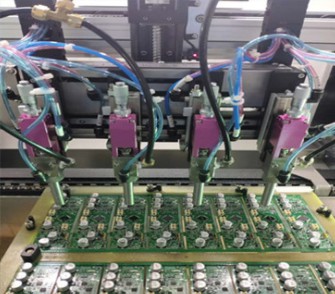

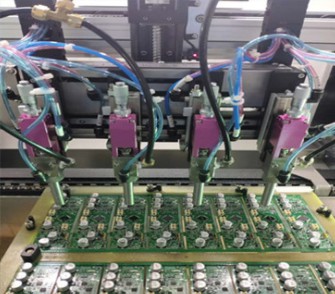

1. 4-Axis Covered Coating System

- The four axes of X, Y, Z and U are all driven by servo motors, which ensures a highly accurate positioning performance.

-

Equipped with additional valve rotation and tilt structure, realizing inclined spraying which can make the bottom of the components coated, and improve the anti-corrosion effect.

-

The coating valve can be rotated 360°.

-

Needle dispensing valve and ace rose dispensing valve can be tilted 45°.

2. Tight Spray Valve Structure

- Used of the latest technology that oriented in Germany, it achieves a high edge definition, no splashing, no block-up, stable and durable, and ensures continuously output of glue.

3. Four Spraying Valves Applicable

- The model can be equipped with maximum 4 spraying valves at the same time, which dramatically improved the production capacity of coating process.

4. Feeding and Cleaning system

-

10L stainless steel inner tank with mixing function feeding barrel.

-

Timed directional cleaning valve to ensure the valve body is clean.

-

Standard 2L cleaning bucket.

-

Feature

1. 4-Axis Covered Coating System

- The four axes of X, Y, Z and U are all driven by servo motors, which ensures a highly accurate positioning performance.

-

Equipped with additional valve rotation and tilt structure, realizing inclined spraying which can make the bottom of the components coated, and improve the anti-corrosion effect.

-

The coating valve can be rotated 360°.

-

Needle dispensing valve and ace rose dispensing valve can be tilted 45°.

2. Tight Spray Valve Structure

- Used of the latest technology that oriented in Germany, it achieves a high edge definition, no splashing, no block-up, stable and durable, and ensures continuously output of glue.

3. Four Spraying Valves Applicable

- The model can be equipped with maximum 4 spraying valves at the same time, which dramatically improved the production capacity of coating process.

4. Feeding and Cleaning system

-

10L stainless steel inner tank with mixing function feeding barrel.

-

Timed directional cleaning valve to ensure the valve body is clean.

-

Standard 2L cleaning bucket.

Keywords:

Loader For SMT Line, TV Assembly Line Equipment, SMT Semi AutomatIC Printer Machine, SMT Semi AutomatIC PCB Printer, Fan Reflow Oven, Selective Soldering Wave Machine PCB, SMT Screw Machine Landing, SMT Spring Contact Machine, Machine Production Automatique SMT, SMT Terminal Insertion Machine, SMT Motherboard Assembly Machine, SMT PCB Machine, SMT Off Line AOI Machine, SPI Machine, SMT AOI Machine, Machine Inspection AOI, AutomatIC Soldering Machine Robot, Hot Air Soldering Robot, AutomatIC Stationary Soldering Robot, Usb Cable Soldering Robot, AutomatIC Soldering Robot Machine

I.C.T is a manufacturer of SMT machines. It mainly provides customers with SMT production lines including SMT Stencil Printers, Pick and place machines, Reflow Oven, AOI Machine, Wave Soldering Machine and PCB Handling Machine etc. I.C.T has more than 25 researches on SMT and DIP technology, for the world Customers provide SMT total solutions. There are successful cases of SMT technical team in Asia, Europe, America, Africa, and Australia.

I.C.T provide SMT solutions at various stages according to the different needs of customers. I.C.T is not only a provider of SMT equipment and technology, but also is the customer's escort in the field of SMT and DIP.

Welcome more people to discuss with us about SMT technologies and solutions, please contact us for more information:

Tel: +86 13670124230 (WhatsApp/Skype/WeChat)

Email: etasmt@foxmail.com