Lead Free Reflow Oven – 6 Zone

From: Author:Reflow Oven Publish time:2021-09-16 16:11 Clicks:0

This convection reflow oven is ideal for mid-to-high volume lead-free soldering production lines.

- 6 upper and 6 bottom forced hot air convection zones allow high quality lead-free soldering with uniform heating and exceptional process stability

- Temperature accuracy of ±1°C and a high-speed CE certificated blower for maximum convection

- Individual temperature control for all zones

OVERVIEW

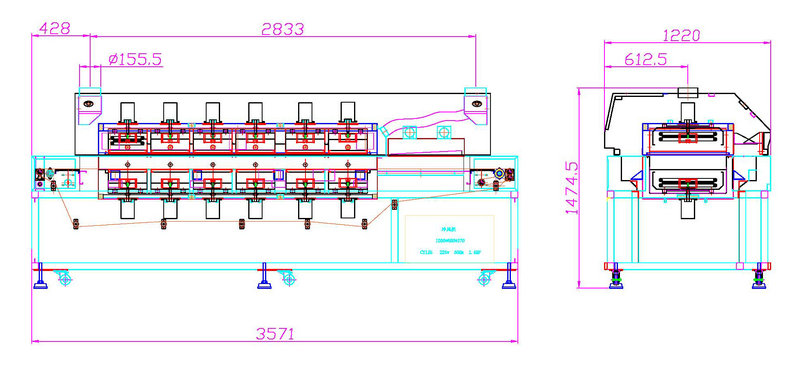

Touchscreen controlled lead-free reflow oven with 6 up and 6 bottom full hot air convection and buit-in chiller cooling zone. Pin-chain/mesh belt conveyor for ideal for inline production

This convection reflow oven is ideal for mid-to-high volume lead-free soldering production lines.

- 6 upper and 6 bottom forced hot air convection zones allow high quality lead-free soldering with uniform heating and exceptional process stability

- Temperature accuracy of ±1°C and a high-speed CE certificated blower for maximum convection

- Individual temperature control for all zones

MAIN FEATURES

- PLC controller, PC and on-line UPS form a stable, safe and efficient controlling system

- The software has functions like: temperature setting and editing, PCB parameter menu, profile testing, alarms and multi-language conversion

- Brand electrical component like Schneider (German) breaker, KETE(Korea) SSR, Omron (Japan) box breaker. Meanwhile the CE certificated blower is specially design for lead-free reflow oven. Making it run very stable and making very low noise

- Upper zone and hood can be opened with electrical screw. It is very convenient for cleaning and maintenance

- Specially designed Ni-Cr heater filaments, provide a very quick ramp up time. It only takes 15 minutes from ambient to setting temperature

- The inner tunnel of the oven is made of stainless steel making it easy to clean

- The entire upper and bottom zones are forced air convection, providing accurate and uniform temperature

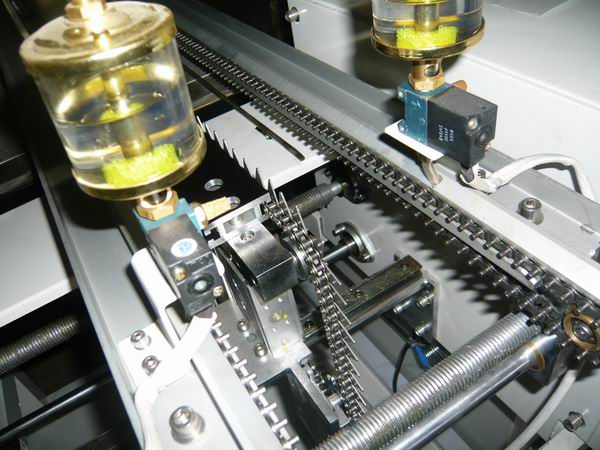

- Stainless steel mesh belt and pin chain conveyor work together

- Built-in industrial chiller provides better cooling performance

CONVEYOR

Chain and mesh belt conveyor can accept boards up to 400m (16") and handle speeds up to 1200 mm/min (47"/min). All rail has been harden-treated and comes with lubrication cup

HEATING ZONES

With 6 upper and 6 bottom forced hot air heating zones get full profile control. Ideal for mid to high production.

BUILT-IN CHILLER

The built-in chiller provides powerful cold wind to the cooling system, helping you control the cooling of lead-free solders.

TOUCHSCREEN INTERFACE

The touchscreen interface allows you to save more than 50 groups of parameters including temperatures, speed and alarm. It also comes with 2 extra thermocouple ports for profiling.

SPECS

| Heating Zones |

Upper 6 hot air zones Bottom 6 hot air zones |

| Heating Method | Fully forced air convection |

| N2 Available | Optional |

| Lead Free | Yes |

| Conveyor Type | Stainless steel mesh belt and Pin Chain conveyor |

| Snema Connection | Yes |

| Component Max. Height | 30mm (1.2") upper, 25mm (1")lower |

| Pcb Width | 400mm (16") |

| Mesh Belt Width | 450mm (17.5") |

| Conveyor Height | 900mm ± 20mm (35" ± 1") |

| Conveyor Speed | 100mm - 1200mm (4" - 47"/min) |

| Center Board Support System | Optional |

| Dual Rail Conveyor System | Optional |

| Heated Tunnel Length | 1.93m (6.5ft) |

| Temperature Accuracy | ±1 °C |

| Delta T | ±2 °C |

| Pid | Yes |

| Ramp Time from Room Temperature to 260 Deg C | < 15 mins |

| Flux Management | Optional |

| Number of Cooling Zones | 1 |

| Cooling Method | Industrial chiller |

| Control | Touch screen + PLC |

| On Board Profiling | Yes |

| Dimensions | L3.5mxW1.2mxH1.45m (L11.5ftxW3.9ftxH4.75ft) |

| Weight | 1100Kg (2425Lbs) |

| Power | 41Kw |

| Exhausting Flow Per Port | 500cmb/hour |

| Number Of Exhausting Port | 2 |

| Ups System | Optional |

| Hood Opening | Air-spring support |

| Package | Vacuuming package and crate |

| Free Spare Parts | Yes |

Keywords:

AutomatIC LED Bulb Production Line SMT Machine, LED Assembly Line, Solder Paste Printer Machine, Dek Solder Paste Printer, Reflow Soldering Oven, Reflow Oven Machine, Wave Soldering Machine Green, Soldering Machine 150-200W For SMT, SMT Machine PICk And Place 36 Va, SMT PICk And Place Machine In India, SMT PICk And Place Machine Ring LED, SMT SMD Manual PICk And Place Machine, 8 Heads SMT PICk And Place Machine, Loader SMT, Loader Machine SMT, SMT Loader And Unloader, Full AutomatIC Loader SMT Machine, SMT Unloading Machine, Machine Depaneling PCB, PCB Depaneling Vision, Hook Knife PCB Depaneling Machine

Keywords:

AutomatIC LED Bulb Production Line SMT Machine, LED Assembly Line, Solder Paste Printer Machine, Dek Solder Paste Printer, Reflow Soldering Oven, Reflow Oven Machine, Wave Soldering Machine Green, Soldering Machine 150-200W For SMT, SMT Machine PICk And Place 36 Va, SMT PICk And Place Machine In India, SMT PICk And Place Machine Ring LED, SMT SMD Manual PICk And Place Machine, 8 Heads SMT PICk And Place Machine, Loader SMT, Loader Machine SMT, SMT Loader And Unloader, Full AutomatIC Loader SMT Machine, SMT Unloading Machine, Machine Depaneling PCB, PCB Depaneling Vision, Hook Knife PCB Depaneling Machine