LEAD-FREE WAVE SOLDERING

From: Author: Publish time:2021-09-17 15:04 Clicks:0

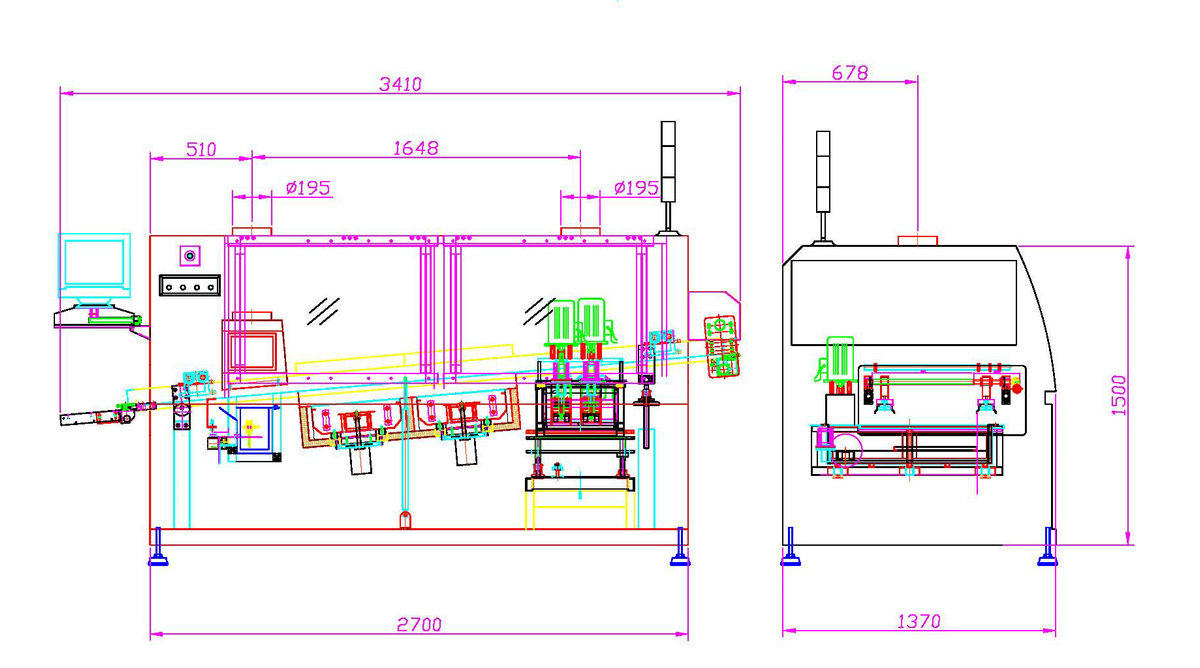

Touchscreen controlled Lead-free wave solder with titanium finger conveyor/stepper controlled spray fluxer. Two hot air preheating zones and pure titanium solder pot.

OVERVIEW

- The one-week timer allows the operator to edit his work schedule for this wave solder machine weekly. The machine can turn on automatically to melt the solder before operator comes to work. This can save about 1.5 hours of work everyday

- Sprayer droved by stepper motor, the speed can be set on PC

- Dual wave solder. Both wave heights are controlled by transducer via touch screen. Changing the wave height via adjusting the frequency of power

MAIN FEATURES

- A new streamline design replaces a conventional right-angled exterior. And the design is based on mechanical aesthetics and practicability, making the maintenance an easy job.

- PLC controller, PC and on-line UPS form a stable, safe and efficient controlling system. Optional with Touchscreen and PLC for controlling system.

- The software has the functions like temperature setting and editing, PCB parameter menu, and profile testing, alarms and muti-languages conversion. In the meanwhile, the software has make a lots effect about the safety issues just like wave motor running safe temperature, safe power off machine.

- The one-week timer will provide a amazing function for customer. The operator can edit his work schedule for this wave solder machine weekly. And the machine can turn on automatically to melt the solder before operator come to work. When it’s time to work, the solder has been melt and everything is ready. It will save about 1.5 hours for customer everyday.

- The specially designed guiding rail reduce the deformation caused by heat; After two years working you only need to change the copper bars instead of change the whole conveyor rails.

- Sprayer droved by stepper motor , the speed can be set on PC. The moving and stopping time will be set in a more precious way.

- The sprayer is made in Japan, it provides perfect atomization performance of the flux.

- Temperature controller in PID model. The preheat zone will provide enough uniform heat for the PCB.

- 2 individual bottom hot air zone, this configuration will provide the greatest preheating effect for soldering.

- Adopt cast iron heater for the solder pot, it’s mounted outside of the solder pot. This new assembling way will prolong the life of the solder pot.

- Dual wave solder. Both wave heights are controlled by transducer. Changing the wave height via adjusting the frequency of power.

- Solder pot is made of Ti material. Long life warranty.

- High quality B&M wave motor which made in Italian, small noise and more stable.

IN-LOADING SYSTEM

Including a sensor in the bottom for couning and an on/off button for the spray fluxer, this system can connect directly to the insertion conveyor. Once inside, you can choose between how the titanium finger conveyor works, "L" finger for pallet, or dual hook finger for PCB.

SPRAY FLUXER

An air supply allows the spray fluxing system to work with air flow pressure. The flow pressure is adjustable by pressure parameters and at each meter there are recommended setting parameters for operator's reference.

SOLDER POT

The solder pot is 3mm thickness pure titanium made. It can be moved in/out and up/down automatically. Really easy to swap between leaded and lead-free. The Italy-made wave motor will keep the wave stable and assure long lifetime

TRANSPARENT GLASS COVER

This cover for preheating zone, allows monitoring PCB runs by eyes. The heaters and blowers can be drawn out from the machine making maintenance much easier.

SPECS

| PBC Width | 1.18-15.75in |

| Pot Volume | 859.8 lbs |

| General Power | 22KW |

| Running Power | 7.5KW |

| Machine Dimension | 123.62(L)49.21(W)62.99(H) |

| Net Weight | 1,653.46 |

| Controlling System | Touch Screen control |

| Conveyor Motor | 1Ph 220V, 60W |

| Conveyor Speed | 7.87in-59.06in/min |

| Flux Volume | 6.5 liters |

| Alcohol Volume | 4.5 Liters |

| PCB Direction | Left to Right |

| Spray Drive | Air cylinder drive |

| Sprayer | ST-6 made in Japan |

| Preheat | 2 hot air convection zone/31.5in length |

| Preheat Power | 4kw/zone |

| Solder Pot Material | Ti |

| Solder Pot Heater | Cast Iron Heaters |

| Solder Pot Power | 1.2KW*10PCS |

| Wave Number | Dual Waves |

| Wave Type | Turbulent first wave, Lambda second wave |

| Time for Solder Melt | 60 minutes |

| Solder Pot Upper/Down | Manual |

| Solder Pot In/Out | Manual |

| Finger Cleaning Pump | 1PH 220V 10W |

| Conveyor Type | Hook Ti finger |

| Solder Angle | 3-6° |

| Air Supply | 3-5 BAR |

| Power Supply | 3PH 220V 60HZ OR 3PH 380V 50HZ OR 3PH 440V 60HZ |

I.C.T is a manufacturer of SMT machines. It mainly provides customers with SMT production lines including SMT Stencil Printers, Pick and place machines, Reflow Oven, AOI Machine, Wave Soldering Machine and PCB Handling Machine etc. I.C.T has more than 25 researches on SMT and DIP technology, for the world Customers provide SMT total solutions. There are successful cases of SMT technical team in Asia, Europe, America, Africa, and Australia.

I.C.T provide SMT solutions at various stages according to the different needs of customers. I.C.T is not only a provider of SMT equipment and technology, but also is the customer's escort in the field of SMT and DIP.

Welcome more people to discuss with us about SMT technologies and solutions, please contact us for more information:

Tel: +86 13670124230 (WhatsApp/Skype/WeChat)

Email: etasmt@foxmail.com

Keywords:

LED Lamp Machine Assembly Line, LED Bulb Assembly Machine Line, SMT AutomatIC Printer, Kik Reflow Oven Profiler, Acrab 450 Wave Soldering Machine, SMT Fuji Machine, PICk And Place SMT, SMD PICk And Place Machine Fully AutomatIC, PanasonIC SMT Machin, SMT Machine Low Production, Desktop PICk And Place, MICro Robot PICk And Place, , PCBA Cleaning Machine, PCB Cleaning Machine, PCB Cleaner, Stencil Cleaning Machine, Stencil Cleaner, Machine Clean LED PCB, RobotIC Arm Screw, Inline Screw Robot, Desktop RobotIC Screw Fastening, Auto Fastening Auto-Screwdriving Machine AutomatIC Fixing Screw Robot