MULTILAYER BOARD FABRICATION INNER LAYER IMAGING

From: Author:MULTILAYER BOARD Publish time:2021-09-17 15:46 Clicks:0

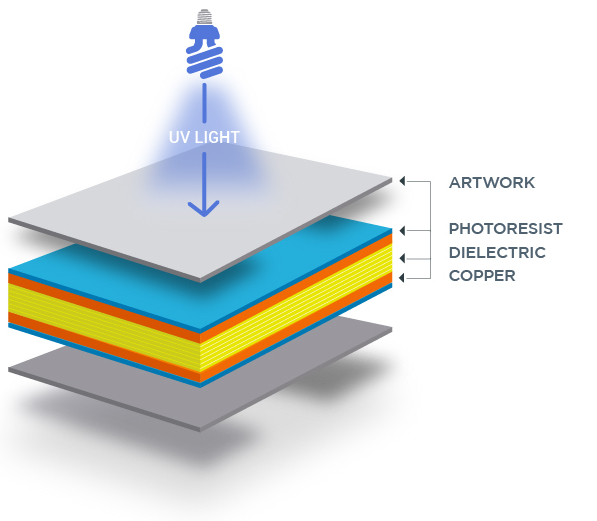

The first step in building a multilayer printed circuit board is to fabricate the inner layers. The inner layer fabrication process begins with transferring the circuit pattern onto the panel. Circuit patterns are transferred to the panel using a photographic process via photoresist, the photo tool and high intensity light. Photo resist is light sensitive and polymerizes when exposed to light. The first steps in fabricating an inner layer is cleaning the inner layer copper surface and then coating both sides with photoresist aka dryfilm. Next the photo tool is aligned to the panel and, the image is transferred from the photo tool to the inner layer by exposing the dryfilm to high intensity light through clear areas of the photo

tool. In the case of a print and etch inner layer, the resist which is exposed to the light polymerizes and remains during the dryfilm developing operation.

I.C.T is a manufacturer of SMT machines. It mainly provides customers with SMT production lines including SMT Stencil Printers, Pick and place machines, Reflow Oven, AOI Machine, Wave Soldering Machine and PCB Handling Machine etc. I.C.T has more than 25 researches on SMT and DIP technology, for the world Customers provide SMT total solutions. There are successful cases of SMT technical team in Asia, Europe, America, Africa, and Australia.

I.C.T provide SMT solutions at various stages according to the different needs of customers. I.C.T is not only a provider of SMT equipment and technology, but also is the customer's escort in the field of SMT and DIP.

Welcome more people to discuss with us about SMT technologies and solutions, please contact us for more information:

Tel: +86 13670124230 (WhatsApp/Skype/WeChat)

Email: etasmt@foxmail.com

Keywords:

Assembly Line For TV, Reflow Oven Soldering Machine, Auto Wave Soldering Machine, PICk And Place Ampoule Machine, SMT Mini PICk And Place Machine, LED Light PICk And Place Machine, PICk And Place Composants ElectronICs Machine, AutomatIC PICk And Place Sheet Machine, Table Top PICk And Place Machine, Stencil Cleaning Machine 850, SMT Line Auto Aqueous Stencil Cleaning Machine, PneumatIC Stencil Cleaner Machine And Stencil Wash, Stencil Washing Machine, Fixtures UltrasonIC Cleaning Machine, , Soldering Robot PCB SMD, Desktop Toy PCB AutomatIC Soldering Robot