DRILLING - HOLE METALLIZATION

From: Author: Publish time:2021-09-17 15:49 Clicks:0

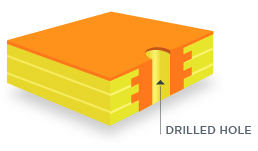

DRILLING

The drilling of the holes is performed on a wide range of CNC machine types. Simpler boards may be drilled with older machine designs that work quite satisfactorily. More complex and denser boards are typically drilled with newer machine designs which have higher rpm spindles, drill extremely fast and are much more accurate. In addition, they may have a tool belt that can hold thousands of tools, a CCD camera for panel alignment and an auto loader and unloader for improved throughput. The panels are drilled for connection to the inner layers, through hole components and mounting holes.

HOLE METALLIZATION

After drilling the holes need to be metallized in order to make electrical connection to the inner layers. The first step in the process is to desmear the holes. The desmear process is designed to remove any resin smear from the drill operation which may electrically insulate the connection to the inner layer or reduce the strength of the plating adhesion to the inner layer. The desmear operation will also, clean the hole of loose debris and add topography to the hole wall for increased adhesion of the initial metallization layer. The second step is to add a thin layer of copper or carbon to the hole wall that will allow for subsequent plating operations.

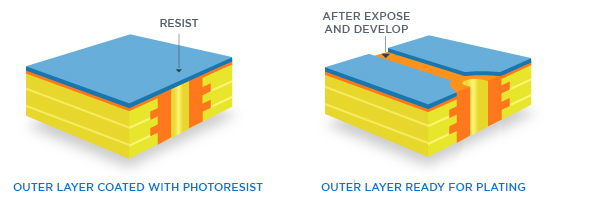

OUTER LAYER IMAGING

Prior to electroplating the circuit image must be transferred to the outer layers. For the outer layers a reverse outwork is applied. The unwanted areas will be covered by the resist and the designed pattern will be exposed.

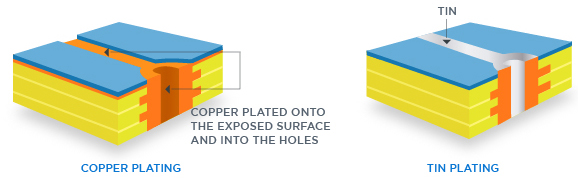

FINISH PLATING

There are various types of plating metallurgies and types of plating options. The most common is pattern plating with a copper plate followed by a tin plate. The copper is required for through hole reliability and current carrying purposes. The tin is required as an etch resist during a subsequent etching operation. Plating of copper in the holes is typically 0.001” followed by a tin plating of 0.0003”. Copper is by far the most common plated metal due to its low cost, easily controlled, and the mechanical/electrical properties are both good.

TIN PLATING

The panels are then plated with tin, protecting the traces, pads and holes from being etched away when the unwanted copper is removed.

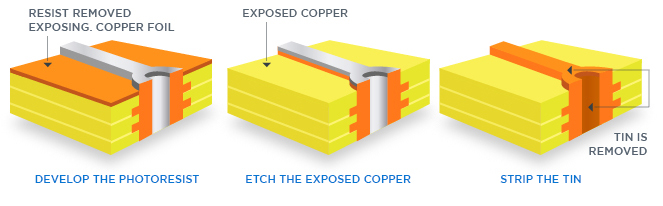

RESIST STIP/ETCH/TIN STRIP

After electroplating the photoresist is stripped from the panel which exposes the background copper for etching. The etching process etches away the exposed copper and the tin protects the copper traces from the top. Some sidewall attack take place on the traces but is compensated for by CAM. After etching the tin is stripped away leaving the copper traces and the plated holes.

SOLDER MASK/LEGEND

Solder mask has several purposes ranging from protecting the traces during assembly operations, defining pads during soldering operations, electrical isolation and protection from the environment. Solder mask and legend inks come in a variety of colors and finishes with green being the most common. Solder mask is typically applied by either screening or spraying. The most common solder masks are photo imageable. After the solder mask is applied to the panel, the process is like dryfilm photoresists exposing and developing processes.

I.C.T is a manufacturer of SMT machines. It mainly provides customers with SMT production lines including SMT Stencil Printers, Pick and place machines, Reflow Oven, AOI Machine, Wave Soldering Machine and PCB Handling Machine etc. I.C.T has more than 25 researches on SMT and DIP technology, for the world Customers provide SMT total solutions. There are successful cases of SMT technical team in Asia, Europe, America, Africa, and Australia.

I.C.T provide SMT solutions at various stages according to the different needs of customers. I.C.T is not only a provider of SMT equipment and technology, but also is the customer's escort in the field of SMT and DIP.

Welcome more people to discuss with us about SMT technologies and solutions, please contact us for more information:

Tel: +86 13670124230 (WhatsApp/Skype/WeChat)

Email: etasmt@foxmail.com

Keywords:

Complete SMT Line For SMD LED, Ir Reflow Oven, After Wave Solder Cutter Machine, Desktop SMT Machine PICk And Place Machine, Mounting Machine SMT PICk And Place Machine PrICe, PICk And Place And Solder Machine

PICk And Place Machine Sm481, PICk And Place Machine Station, LED Machine PICk And Place, PCB Bord Cutting Manufactur Machine, PCB Sheet Cutting Machine, V Cut PCB Machine, LED PCB Cutting, V-Cut Machine PCB, PCB Cutter Machine Manual Cut, Multiple Sets Of Blade PCB Cutting V Cut Machine, PCB Cutting V