CASTELLATED MOUNTING HOLES IN PCB FABRICATION

From: Author:smt pcb assembly line Publish time:2021-10-04 20:57 Clicks:0

There are generally two types of technologies used during the PCB Assembly process, through hole (THT) and surface mount (SMT). There is another technology that is becoming common these days that is used when there is a need to mount a single module board on top of another PCB, this technology is called board-to-board soldering. Castellated holes (also referred to as castellations) are becoming more common in printed circuit board fabrication as the demand for circuit board modules increases.

WHAT ARE CASTELLATED HOLES?

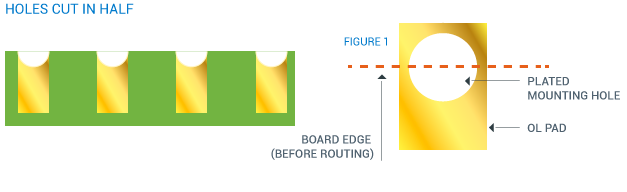

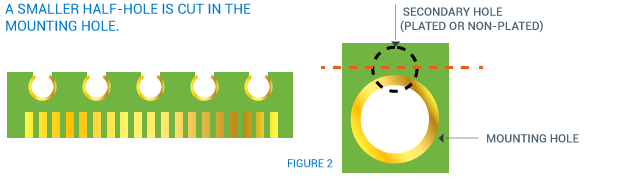

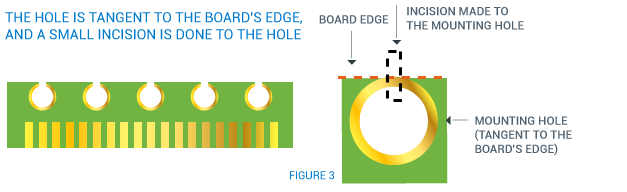

Castellations are plated through holes or vias located in the edges of a printed circuit board. Castellations are cut through to form a series of half holes. These half holes serve as pads intended to create a link between the module board and the board that it will be soldered onto.

WHAT ARE CASTELLATED HOLES USED FOR?

Castellated holes can be used for a couple of different reasons. Most commonly, they are used by designers to create PCB modules, such as Wi-Fi or Bluetooth modules, which will then be used as an independent part to be placed onto another board during the PCB assembly process. However, castellations are also used when combining two boards to ensure the solder inspection joint is properly structured and to create wireless PCB to PCB links.

ARE THERE DIFFERENT DESIGNS FOR CASTELLATED MOUNTING HOLES?

Yes, several. They include:

1. Half Holes.

2. Holes with smaller half holes.

3. Holes tangent to the board's edge.

CASTELLATED HOLES SPECIFICATIONS

Depending on the need and final use of the board there are some design attributes that need to be met. For example:

· Size: It is recommended to use the largest possible size.

· Surface finish: Depends on the final use of the board, but ENIG is recommended.

· OL pad design: It is recommended to use the largest possible OL pad on top and bottom.

· Number of holes: This depends on the design; however, it is known that the less number of holes, the more difficult the PCB Assembly process will be.

Keywords:

SMT Production Line SMT PICk And Place Machine, PCB SMT Line, Vision Stencil Printer, SMT Stencil Printer, T6 Reflow Oven, Reflow Oven PrICe, Wave-Soldering Machine, Automated PICk And Place Packaging Machine, PCB Assembly PICk And Place Machine, AutomatIC Programable PICk And Place Manipulator, 4 Heads PICk And Place Machine, DIP Components PICk And Place Machinery, High Speed PICk And Place Module, R2R PICk And Place Dispense Rfid, Pab Conformal Coating Machine, Conformal Coating Machine PCB, Conformal Coating For PCB Machine, PCB Router InalámbrICo, PCB Circuito Router, PCB Drills And Routers, PCB Circuito Router CNC

I.C.T is a manufacturer of SMT machines. It mainly provides customers with SMT production lines including SMT Stencil Printers, Pick and place machines, Reflow Oven, AOI Machine, Wave Soldering Machine and PCB Handling Machine etc. I.C.T has more than 25 researches on SMT and DIP technology, for the world Customers provide SMT total solutions. There are successful cases of SMT technical team in Asia, Europe, America, Africa, and Australia.

I.C.T provide SMT solutions at various stages according to the different needs of customers. I.C.T is not only a provider of SMT equipment and technology, but also is the customer's escort in the field of SMT and DIP.

Welcome more people to discuss with us about SMT technologies and solutions, please contact us for more information:

Tel: +86 13670124230 (WhatsApp/Skype/WeChat)

Email: etasmt@foxmail.com