Content

Smartphone Inline SMT PCBA Router Machine I.C.T-IR180

Introduce:

Introduce:

High quality PCBA router machine, inline PCB router, PCB V-cut machine, PCB separator, LED depaneling, for PCBA cutting.

I.C.T inline pcba router is a high-precision high-speed dual-platform on-line PCBA router, which is used in smart phones, smart wear, smart home, tablet computers, automotive electronics, medical devices, aerospace, military and other fields.

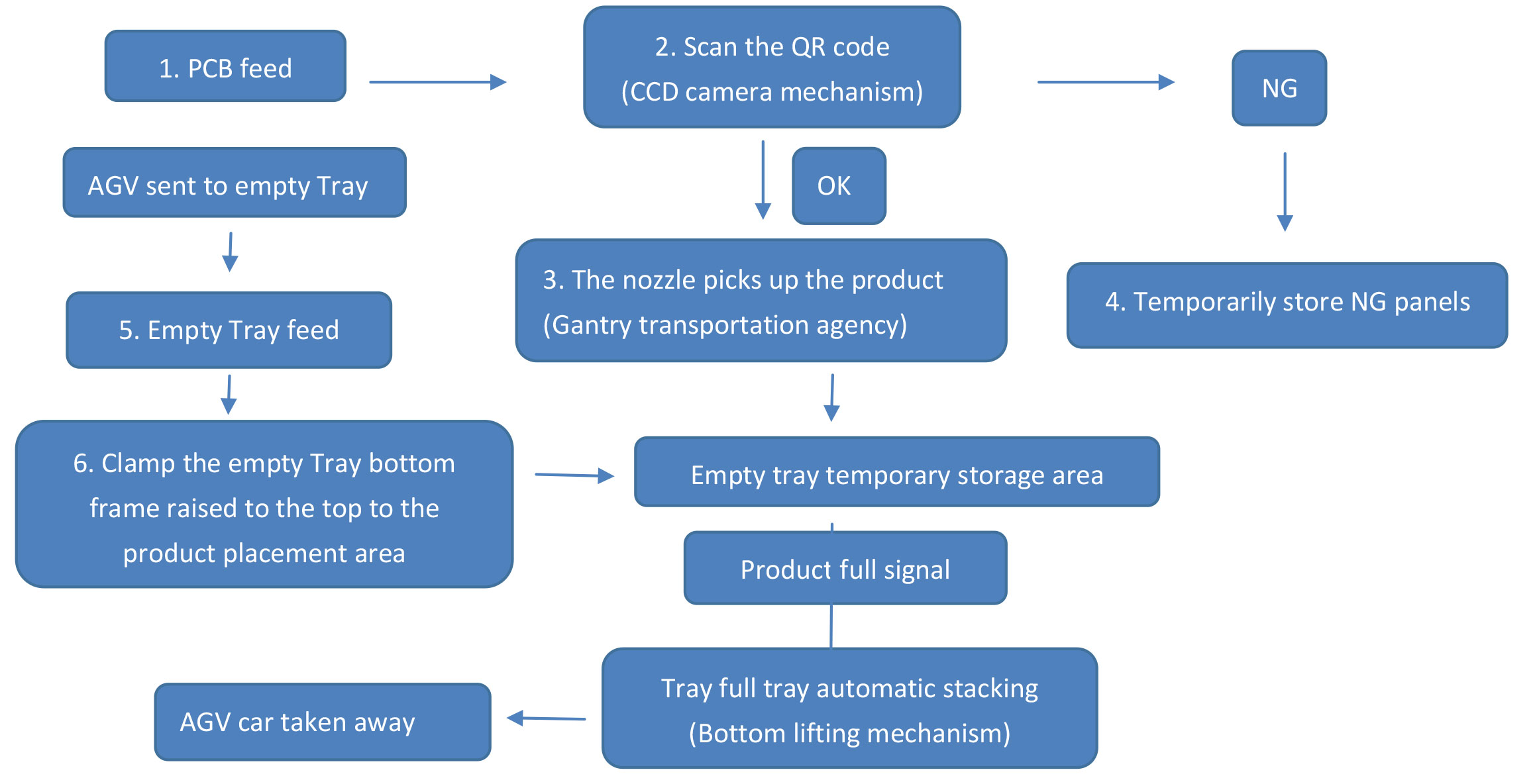

Automatic PCBA Placement Machine

1. Automatic feeding: auto feed the products to be placed in the plate after receiving the signal from the front machine.

2. Automatic code scanning: CCD detects the product size and has the code scanning function at the same time.

3. Automatic pan: CCD guides the suction nozzle to automatically suck OK products to pan.

4. Automatically distinguish NG code: NG products are automatically put into the NG plate, and the NG code and fork plate are put into the defective box.

5. Automatic stacking tray: automatically supply empty trays and stacking OK finished trays full trays.

6. AGV automatically feeds in empty trays and takes away full trays.

Process:

-

New CCD system,new vision system can correspond to all kinds of pcb mark.with visual counterpoint correction function.

-

The sensor can monitor the milling cutter state in real time, and effectively prevent the continuous operation of the cutter.

-

Using high speed spindle, cutting stress is greatly reduced, precision is high, inertia is small, and response is fast.

-

Ion air gun will remove static electricity on PCB surface and prevent dust from adsorbing on PCB.

-

Automatic loadering - picking and placing – cutting – unloadering pcba,unloadering solution can be option.

-

Adopt CNC special controller,high stability and strong anti-interference.

-

The separated vacuum dust collector adopts high efficiency motor with high suction and low noise.

-

Realize automation, save manpower and improve quality.

-

Automatic storage product information, automatic adjustment conveyor width, improve the speed of line change.

-

Loadering pcba the automatic splint function replaces the traditional cylinder and is more accurate.

-

Dual working platform to improve cutting efficiency.

-

Pcba can be cut and move at the same time to improve productivity efficiency.

-

Standard MES or ERP connection ports, real-time connection to the central database.

-

Bar code camera is option, which can scan barcode automatically and upload.

Feeding System:

|

Pick & Place System: |

|

CCD camera alignment system, Milling cutter Auto-change system |

| PCB Router | I.C.T-IR180 |

| Pcb Size(Special size optional) | 180*180mm |

| PCB thickness | 0.3~4.0mm |

| Operation and Data Storage | PC System |

| Dimension | 800*1350*1700mm |

| Weight | 1100kg |

| Dust Collector | |

| Dust Collection Method | Vacuum cleaning |

| Air volume of vacuum cleaner | 12~20cm3/min |

| Vacuum cleaner Dimension | 750*600*620mm |

| Voltage of the Dust Collector | 380V,50/60HZ, 1.2kw |