Content

I.C.T X-7200 | Offline SMT PCB X-ray Inspection Machine

Features:

1. CNC program: automatic batch detection of different positions of samples.

2. Array function: automatic batch detection of samples with fixed positions and the same spacing.

3. Length and width measurement: measure the length and width of part of the detection area.

4. Visual navigation interface: precise positioning of the detection position.

5. Simulate color: better observe the inspection image.

6. Bubble measurement: One-key measurement of bubble size, void rate, and tin climbing height.

7. Automatically ON/OFF X-RAY light tube to detect samples in batches.

8. Equipped with high stability and high precision X-ray light tube.

9. High-resolution digital X-RAY flat panel.

10. The stage can accommodate a large number of samples of various sizes.

11. Optional 360° rotation of the stage to detect samples.

12. Allows 60° tilt observation.

13. High safety, with EU CE Certificate, International Quality Management System ISO, and AERB Certificate for X-ray.

Joystick Control

Programming Control

Optional: Digital HD X-RAY flat detector

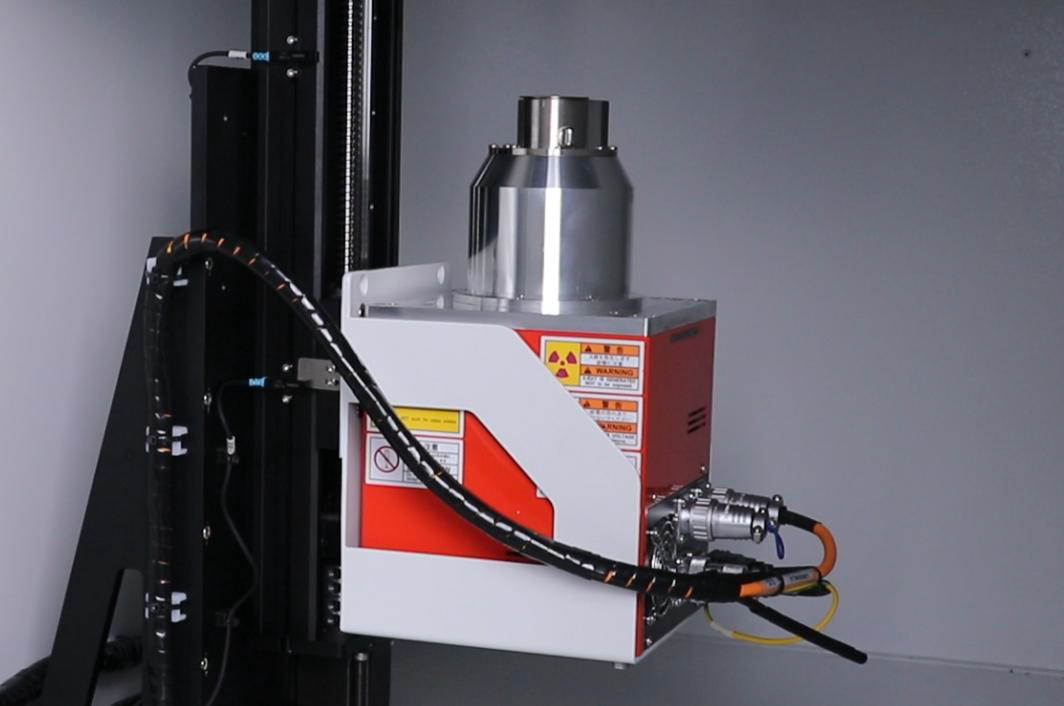

XRAY Tube

Application of X-ray Inspection Machine :

SMT, BGA, PCBA assembly, Router, Lithium battery, Wire harness, Wire rod, Display, Fuse, Electronic components, Automotive parts, Photo-voltaic, Aluminium die-casting, Moulding plastic, Ceramics, other special industries.

Router

Wire rod

Electronic harness

Electronic sensor

Battery protection board

Display

Lithium battery

Fuse

Specification of X-ray Inspection Machine:

| Item | Model | I.C.T X-7200 |

| X-Ray Tube |

Type |

Closed tube |

| Voltage | 90kV | |

| Electric current | 200uA | |

| Spatial resolution | 5μm | |

| Flat panel | Image capture method | Flat panel digital imaging |

| Imaging accuracy | 85μm | |

| A/D conversion quantized density value | 16bit (65536) | |

| Resolution | 1280*1024px | |

| Acquisition frame rate | 30 FPS | |

| System | Magnification | 200x |

| Operating system | Windows 10 | |

| Power | AC110-220V, 50-60HZ, 1200W | |

| Radiation safety test | <1 uSV/H | |

| Structure | Max. Loading size | 540mm*540mm |

| Max. Inspection area | 510mm*510mm | |

| Max. Loading weight | ≤10kg | |

| Platform rotation angle | 60° | |

| Dimension | 1100*1360*1750mm | |

| Weight | 950kg | |

| Platform movement | Automatic / Manual |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

Successful Experience:

I.C.T's Customer In 75 Countries Around the World

1. We Have Been Helping Customers To Build a Lot of New Factories Around the World.

2. Training More Than 790 Experts and Technician for Customers.

3. Became the Most Reliable Chinese Partner for You.

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

5. We Can Solve Any Question About SMT

❙ I.C.T Exhibition

❙ I.C.T Global Service

Successful Experience:

I.C.T's Customer In 75 Countries Around the World

1. We Have Been Helping Customers To Build a Lot of New Factories Around the World.

2. Training More Than 790 Experts and Technician for Customers.

3. Became the Most Reliable Chinese Partner for You.

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

5. We Can Solve Any Question About SMT

❙ I.C.T Exhibition

❙ I.C.T Global Service