Content

Intelligent SMD Storage System

Be smart when it comes to SMD storage of your SMD components

Features of Intelligent SMD Storage System:

1. Only the reels you need are unloaded.Direct handling brings a whole new level of efficiency to tasks;

2. Dedicated multifunctional unloading platform, even reels of different sizes can be unloaded;

3. Direct handling eliminates the need for dedicated storage boxes for reel assemblies and saves the space cost of dedicated storage boxes;

4. Batch Loading / Handling of up to 33 reels, compared to automatic storage that only loads 1 reel at a time, while loading or unloading components, this time can be effectively used for other tasks;

5. The Intelligent Storage System's built-in barcode reader automatically scans barcodes on all reels during batch loading. This prevents read errors caused by human error and eliminates the scanning process, making the receiving process more efficient;

6. Equipped with a temperature and humidity control module, you can choose to control the temperature and humidity inside the Intelligent Storage System 24 hours a day to avoid moisture damage to components;

7. Time limit management, managing time-limited components to avoid component defects caused by missing the use period;

8. Multiple uninstall modes, including first-in-first-out mode, prioritizing use based on production date, prioritizing uninstalling based on current use, etc;

9. "Industry 4.0": Compatible with customers' MES/ERP systems to achieve information sharing and processing.

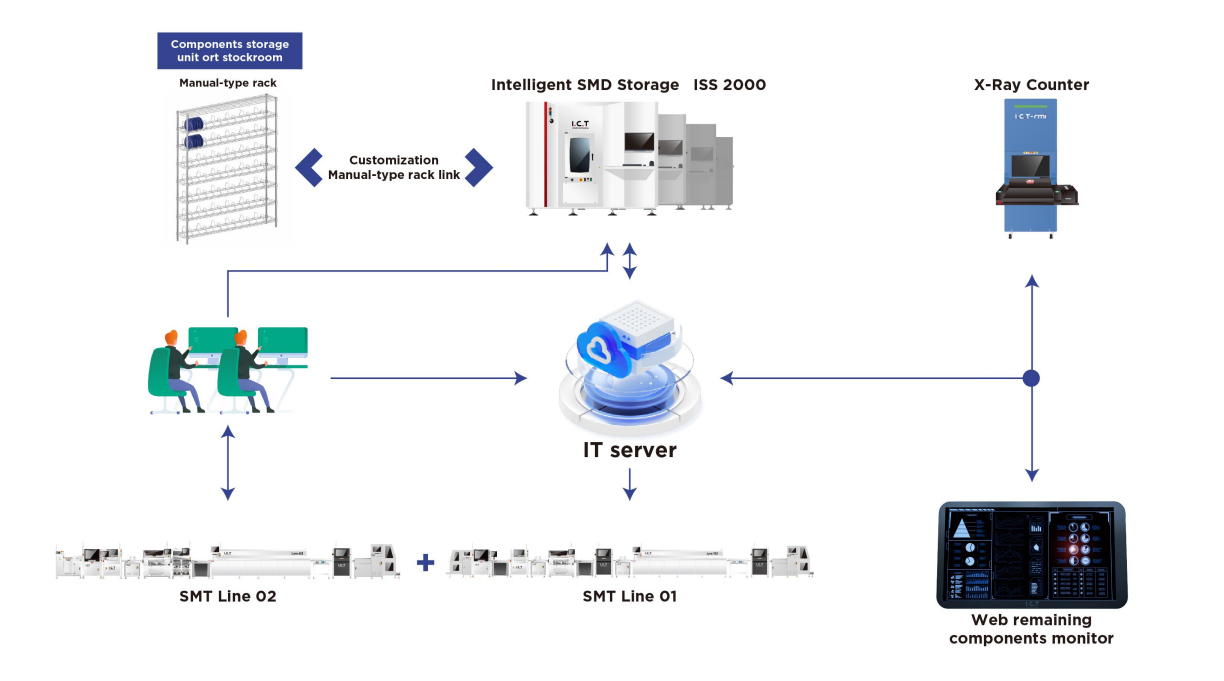

Smart factory:

Excellent error-proofing system, intuitive management method, simple operation, intelligent fool-proofing.

| Model | Intelligent Storage System | |||

| Max reel size (Depending on Configuration) | Reel height | 7” small | 13" wide | 15" Wide |

| 8mm | ok | ok | ok | |

| 12mm | ok | ok | ok | |

| 16mm | ok | ok | ok | |

| 24mm | ok | ok | ok | |

| 32mm | - | ok | ok | |

| 44mm(Option) | - | ok | ok | |

| Max reel weight | 2.0 Kg | |||

| Max reel loading/unloading at once cycle | 35 (Small Configuration) / 25 (Standard & Mixed Configuration) / 8 (Wide) | |||

| Max possible machines to connect | 99 *External server PC is required for 4 or more machines connected. | |||

| Average time for unloading | 15” seconds | |||

| Network | Ethernet LAN | |||

| Display | LCD touch screen | |||

| Operation system | Windows 10 pro | |||

| Power capacity | 1500 VA Standard with dehumidifier | |||

| Power supply | Single phase 110/230V (± 5%), 50/60Hz | |||

| Dimensions (Excluding tower signal) | Standard (with dehumidifiers) | 2715*1620*2450mm | ||

| With extension | 2715*1620*3200mm | |||

| Weight | Standard | 1565Kg | ||

| Extension | 417Kg | |||

* Customized mode please contact I.C.T Team.

Dimensions of Intelligent SMD Storage: